Fork toes are more than simple bent bars of steel.

Our forks are strictly manufactured in accordance with ISO 2328 and ISO 2330.

By using first class raw materials, forks are produced according to customer requirements and the industry’s strictest standards.

QC1

Special two-step shot blast provides better surface and good finish.

QC2

Clear stamping at the shank side with production date, series number and steel batch no.

QC3

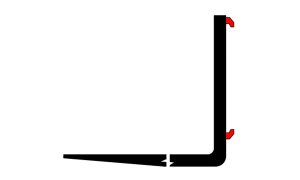

Special treatment at the inside heel removes protruding edges and other imperfections

QC4

Pairing tolerance – strictly conforms to ISO 2328, ISO 2330

QC5

Dye penetration test at the heel to guarantee no visual crack

QC6

Weld ultrasonic test to guarantee no internal crack

QC7

Fully heat treated

QC8

Application test to guarantee 3 times safety factor